Tony Cook had noticed a new and growing problem related to labeling. This problem focused on the horticulture industry, and the fact that it was facing continual growing pressures from “big box” retailers. Barcoding & more precise label placement on plant containers were required to accommodate the new point of purchase selling that was now revolutionizing garden centers.

“One of the many issues growers are faced with is the cost of labor.” – Richard Jones, editor of Greenhouse Grower

With this growing demand, greenhouses would need more laborers. The requirements were changing from just one UPC for 30 different products to an individual UPC for each container size, type, & color. In many cases, this changed the need from 200 bar codes in the past to over 4,000 of them to fit these new requirements. The new point of purchase systems was providing the Garden Centers with more accurate & real-time information on the plants that customers were demanding. These systems were changing the industry to a Just-in-Time ordering system, as retailers began adjusting shipment orders to finally reflect their customers’ needs.

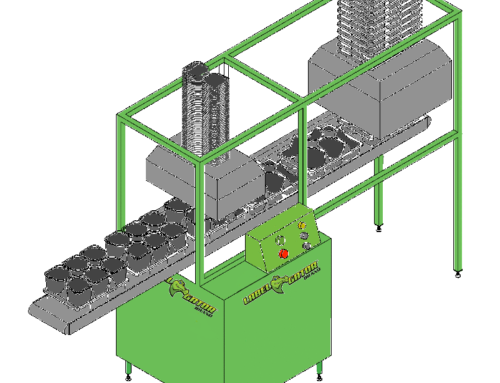

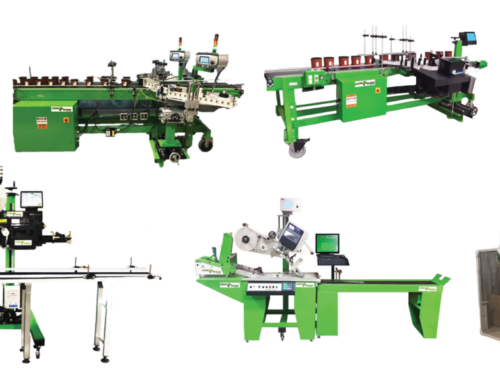

To help growers with these extra costs in labor, for the new requirements, Tony thought he should create an automated solution, specifically with growers in mind. He wanted to create a machine that could print and/or apply labels with precise placement, lower labor costs, increase speed & efficiency, and overall add a positive impact to growers’ greenhouse operations.

Traditional greenhouse operations included hand labeling pots (whether that be inserting tags, locking tags or labels) and the use of many more workers. With all of these new requirements and this new standard & the expectation of universal, precise label placement for one’s shelf appeal, this old way of labeling just wouldn’t cut it anymore.

Traditional greenhouse operations – applying labels by hand.

This is when Tony began to create the solution – The Label Gator® Systems. It is the perfect answer to address all of these challenges. Now growers can precisely label pots with individual, customer-specific labels as needed, and react quickly to order changes. Productivity & delivery speed are significantly increased, while the cost of labor and inventory decreases by automating the labeling process. After a few years of trials, modifications, & prototypes, Cook and his team created the first automated labeling system engineered specifically with growers in mind.